Further, it is widely used in factories today - industrial radiography. It supports businesses so their products are safe and quality. Outsourced element testing company, Dothing uses industrial radiography to improve companies' products. So, as per this, let Us see about the Industrial Radiography and Its significance.

What is Industrial Radiography and How Does It Work

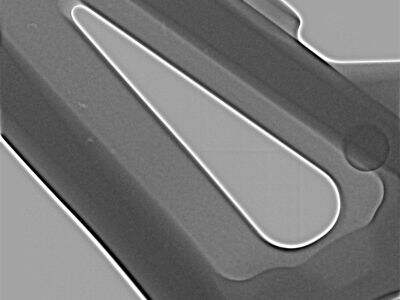

X-rays and gamma rays are used in industrial radiography to photograph the inside of objects. This allows detectiing problems that we may not see from the outside. If a company is creating a part for an airplane, for example, they can learn about what sorts of cracks or weak spots the part has with industrial computed radiography. This is extremely critical for safety.

Evaluating Manufacturing Processes

We can say that industrial radiography also helps check whether every part is being made correctly or not. By taking X-ray photos of parts at the moment of manufacture, companies can confirm that things are in the right place and that they are the right size. This avoids mistakes and helps ensure the quality of the products.

Testing Without Damage

Industrial radiography lets companies try out their products without damaging them. Some other testing methods require cutting or breaking the part, but radiography provides clear images without damaging anything. That means companies are able to verify their products without altering how they operate.”

Keeping Workers Safe

It's crucial for all businesses, particularly in the world of potential accidents. Flaws in these critical components can pose safety risks, and industrial radiography identifies these issues. By catching these issues early on, companies can prevent accidents and protect workers.

Digital Radiography: The New Horizon

Digital radiography has transformed industrial radiography. Digital industrial radiography captures images using sensors instead of film that can be immediately viewed. This allows companies to verify their products faster and with greater accuracy, resulting in improved quality control and expedited production.

EN

EN

ONLINE

ONLINE